Food Processing Turnkey Projects

Food Processing Turnkey Projects Specification

- Process Inclusions

- Cleaning, Sorting, Roasting, Grinding, Packaging

- Phase

- Three Phase

- After Sales Support

- Available

- Control System

- PLC Based

- Energy Efficiency

- High

- Design

- Custom Design as per requirement

- Voltage

- 380-440V

- Operator Training

- Provided

- Raw Material Handling

- Included

- Safety Standards

- Complies with National Food Safety Guidelines

Food Processing Turnkey Projects Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Food Processing Turnkey Projects

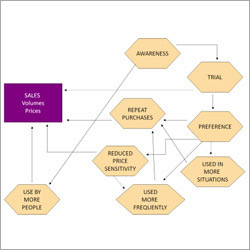

We understand the significance of hiring the right candidate, so that here we are offering our clients service for Food Processing Turnkey Projects. Our team of professionals provides the appropriate location and layout for the food processing industries, selection of manufacturing machines from the reliable vendors of the market, and also provides training programes for these turnkey projects. We assist our clients by giving suggestions related to the processing the food products, installing the modern machines and selling them in market. Provided Food Processing Turnkey Projects are widely appreciated by our clients due to our professional approach and timely completion within budgeted costs.

Comprehensive Custom Design

Every turnkey project is meticulously engineered to align with your specific production requirements. From layout planning to process optimization, our team develops bespoke solutions that maximize efficiency, streamline workflows, and ensure flexibility to accommodate future needs. This approach guarantees that each system integrates seamlessly into your existing operations.

Advanced PLC-Based Control Systems

Our projects incorporate state-of-the-art Programmable Logic Controller (PLC) technology, enabling automated, precise management of each process stage. This not only minimizes human error but also improves reliability and traceability during production, from raw material handling to final packaging.

Unwavering Food Safety and Energy Efficiency

All processing systems comply strictly with national food safety standards, protecting your product integrity and consumer trust. Moreover, our equipment is designed for high energy efficiency, reducing operational costs without compromising performance or output quality.

FAQs of Food Processing Turnkey Projects:

Q: How is the turnkey food processing project customized for specific requirements?

A: Each project is custom designed following an in-depth assessment of your unique production needs, facility layout, and output goals, ensuring seamless integration with existing processes.Q: What food processes are included in your turnkey solutions?

A: We offer complete food processing lines that include cleaning, sorting, roasting, grinding, and packaging, as well as raw material handling, all controlled through an advanced PLC system.Q: Where are your turnkey projects available for installation?

A: Our turnkey projects are available for deployment across India, with full support for exporters, manufacturers, fabricators, importers, suppliers, traders, and service providers.Q: When is operator training provided in the project timeline?

A: Comprehensive operator training is delivered after installation and commissioning, ensuring your personnel can operate and maintain the system confidently from the outset.Q: What are the energy requirements and efficiency features of these systems?

A: The equipment operates on 380-440V three-phase power and utilizes energy-efficient technologies, which help reduce ongoing electricity costs while maintaining high performance.Q: How does the system ensure compliance with food safety standards?

A: All machinery and processes adhere to national food safety guidelines, with design and operation protocols in place to safeguard food safety throughout processing and packaging.Q: What after-sales support and service do you provide?

A: We offer comprehensive after-sales support, including maintenance, troubleshooting, and access to spare parts, ensuring sustained reliability and customer satisfaction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Consultant Category

Corporate Branding Services

Price Range 105000.00 - 101000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Market Development Services

Price Range 101000.00 - 1000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Standardization Services

Price Range 102000.00 - 1000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS